|

Clean water tank volume: 85L

|

Sewage tank volume: 90L

|

|

Absorbent width: 1000mm

|

Washing width: 800mm

|

|

Body weight: 211kg

|

Speed: 230 rpm

|

|

Working efficiency:4500m2/h

|

Number of batteries: 2

|

|

Battery voltage: 24V

|

Battery configuration: 100AH

|

|

Duration: 3.5h

|

Noise: ≤68dba

|

|

External size: 1445mm995mm1100mm

|

|

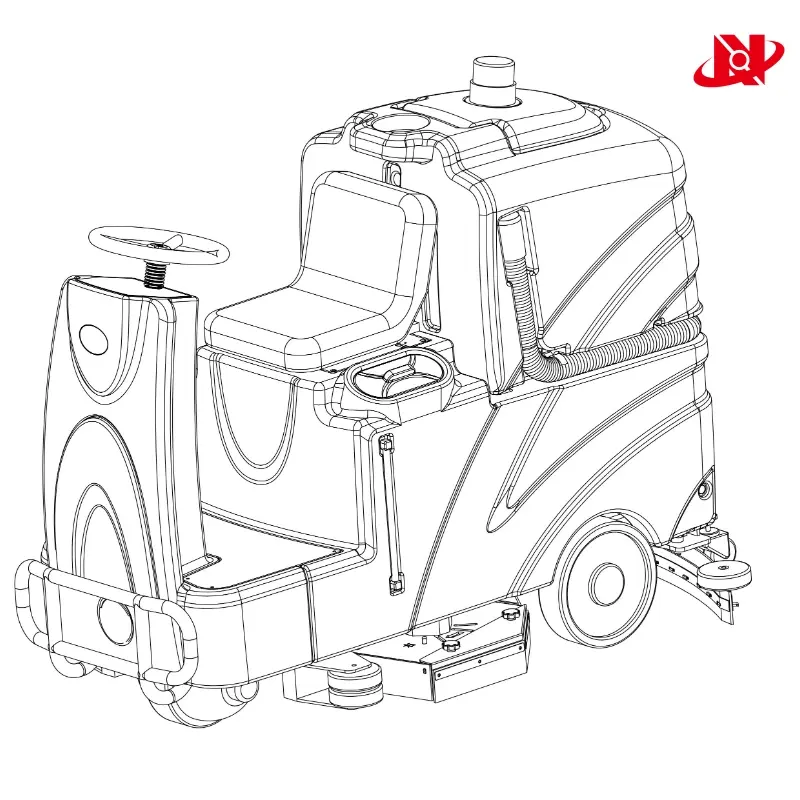

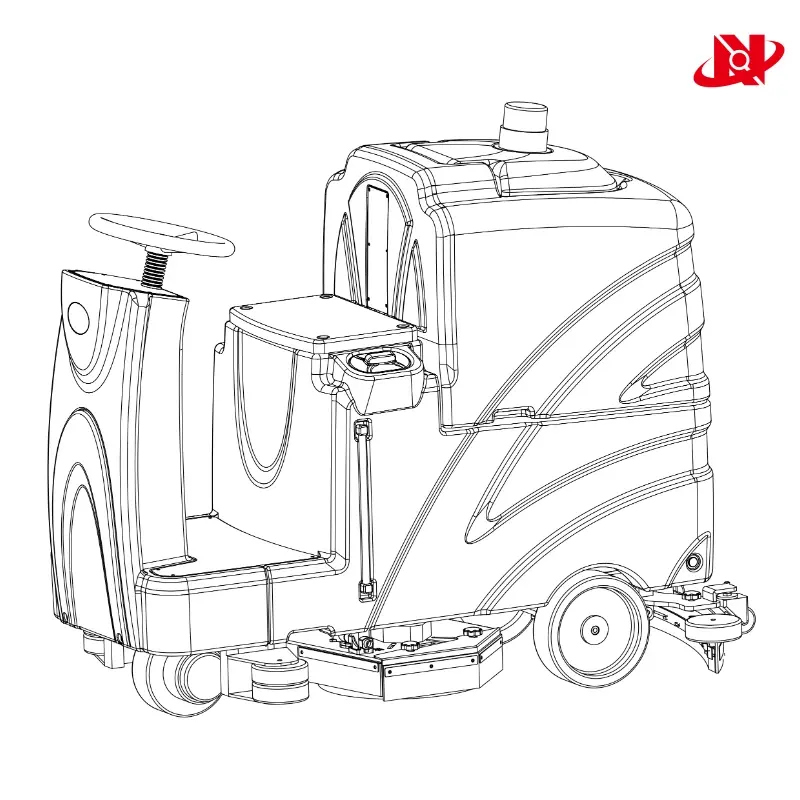

Industrial floor washing machine

- Description

- Download

-

Clean water tank volume: 85L Sewage tank volume: 90L Absorbent width: 1000mm Washing width: 800mm Body weight: 211kg Speed: 230 rpm Working efficiency:4500m2/h Number of batteries: 2 Battery voltage: 24V Battery configuration: 100AH Duration: 3.5h Noise: ≤68dba External size: 1445mm995mm1100mm Working principle

The working principle of the driving-type industrial floor washing machine is to realize the efficient cleaning of the floor through the cooperative operation of the disk brushing system and the absorbent scraping system. The specific process is as follows:

Clean water spraying: clean water in the water tank is transported to the brush tray through the pump, and the spray hole on the brush tray is evenly sprayed on the ground. This process not only wets the floor and softens dirt, but also provides lubrication for the brush wash, reducing friction resistance and protecting the floor and the brush.

Wash the ground: With the high-speed rotation of the brush disc, the brush bristles or cleaning pads produce friction with the ground, and the dirt, dust, oil and other impurities on the ground are involved in the water, and the ground is comprehensively washed. The pressure and speed of the brush disk can be adjusted according to the actual situation to ensure that the ideal cleaning effect can be achieved for different types and degrees of dirt.

Sewage recovery: While washing the floor, the suction scraper system starts to work. The strong suction force will be on the ground with dirt sewage into the sewage tank, sewage through the suction scraper diversion trough and suction pipe, and finally collected into the sewage tank. The suction strip is in close contact with the ground to form a sealed suction channel to ensure that the sewage does not leak and achieve efficient sewage recovery.

Filter cycle (optional) : Some advanced driving industrial floor washers are also equipped with a sewage filter cycle system. After the sewage is sucked into the sewage tank, it will be initially filtered through the filter device to separate the larger impurities. The filtered water can be recycled back to the clean tank for continued cleaning of the ground, thus achieving the purpose of water conservation. However, after repeated use, it is still necessary to replace the water regularly to ensure the cleaning effect. -