| Clean water tank volume: 85L | Sewage tank volume: 90L |

| Absorbent width: 1000mm | Washing width: 800mm |

| Body weight: 211kg | Speed: 230 rpm |

| Working efficiency:4500m2/h | Number of batteries: 2 |

| Battery voltage: 24V | Battery configuration: 100AH |

| Duration: 3.5h | Noise: ≤68dba |

| External size: 1445mm995mm1100mm |

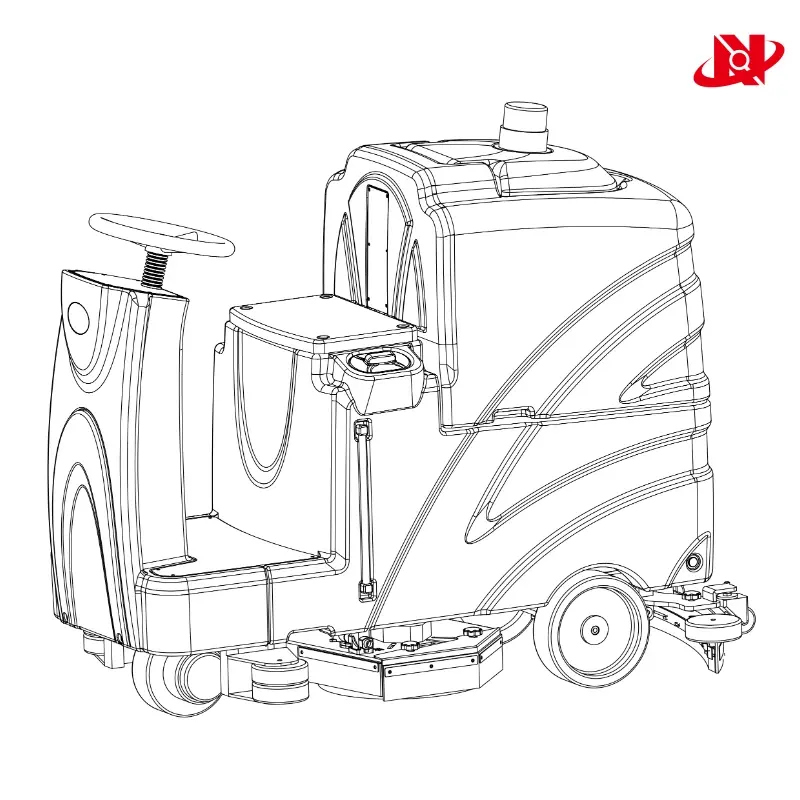

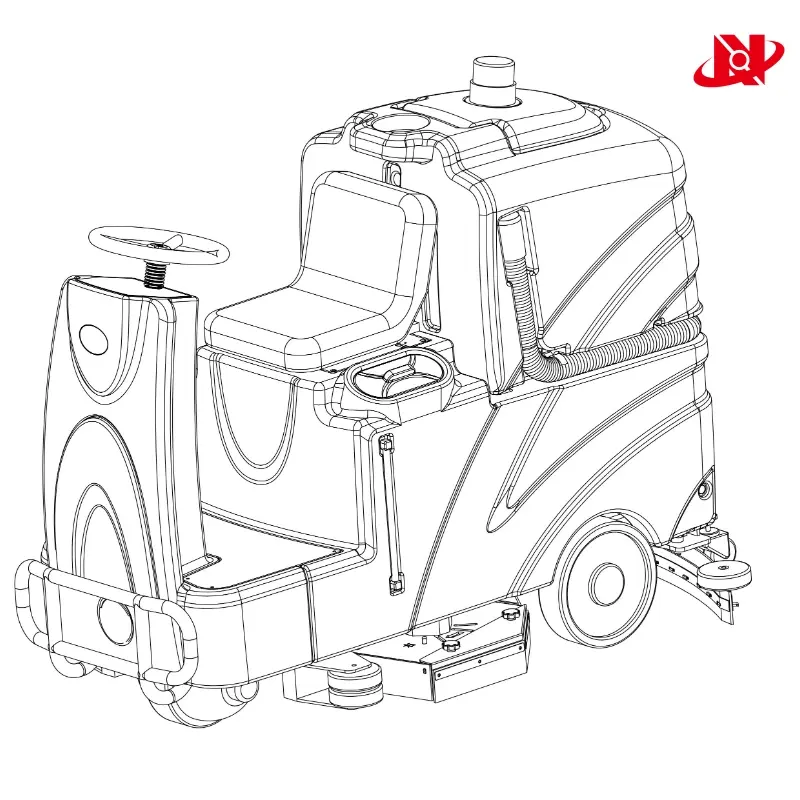

XF-M85B Super clean, super quiet design

- Description

- Download

-

Clean water tank volume: 85L Sewage tank volume: 90L Absorbent width: 1000mm Washing width: 800mm Body weight: 211kg Speed: 230 rpm Working efficiency:4500m2/h Number of batteries: 2 Battery voltage: 24V Battery configuration: 100AH Duration: 3.5h Noise: ≤68dba External size: 1445mm995mm1100mm Cockpit and operating system

Cockpit: The piloted industrial floor washer has a comfortable cockpit and is ergonomically designed. The position, height and Angle of the driver’s seat can be adjusted to suit the body type and driving habits of different operators. The cockpit is also equipped with a dashboard to display the operating status of the machine, such as brush speed, suction motor power, electricity or oil (if it is fuel driven).

Operating system: The operation control lever is usually located on both sides of the driver’s seat, which is convenient for the operator to control the forward, backward, steering and other actions of the machine. At the same time, there are a series of buttons and knobs on the operating table, which are used to control the rotation of the brush disk, the opening and closing of the suction motor, the amount of cleaning water spraying and other cleaning functions.

Cleaning system

Brush plate assembly: including brush plate motor, brush plate and brush plate support. The power of the brush motor is large and can provide enough torque to drive the brush disk to rotate at high speed. The size of the brush tray varies according to the machine model, and the diameter is generally ranging from tens of centimeters to more than one meter. The bristles of the brush tray are of various materials, such as nylon bristles for cleaning hard ground, and softer bristles are suitable for places with high ground surface requirements, such as epoxy floors.

Absorbent assembly: mainly composed of absorbent motor, absorbent body and absorbent rubber strip. The suction generated by the suction motor can ensure that the sewage is sucked into the sewage tank in a timely and effective manner. The structural design of the absorbent body enables it to closely fit the ground, and the absorbent strip is a key component that directly touches the ground and absorbs water, which needs to be checked and replaced regularly to ensure a good absorbent effect.

Water tank system

Clean water tank: used to store clean water, the capacity is generally between several hundred liters and thousands of liters, to meet the needs of large areas of cleaning. The water tank is usually equipped with a water level sensor, which alerts when the water level is too low to remind the operator to add water in time. At the same time, there is a water injection port and a filter device, which can prevent impurities in the water from entering the cleaning system and damaging the nozzle or brush tray.

Sewage tank: used to collect sewage after cleaning the brush tray. The sewage tank also has a level sensor that prompts the operator to dump the sewage when it reaches a certain capacity. Its drain design is convenient and fast, and some also have automatic drainage function, which is convenient to quickly clean the sewage tank after the cleaning work is finished.

Dynamic system

Electric drive: The use of large capacity battery as a power source, this drive is environmentally friendly and quiet. Battery life varies according to the model and use of the machine, generally can continue to work for several hours. Charging systems are often designed for smart charging, which protects the battery and extends its service life -