| Technical parameters: | |

| Clean water tank volume: 45L | Sewage tank volume: 50L |

| Absorbent width: 860mm | Washing width: 510mm |

| Body weight: 150kg | Speed: 180rpm |

| Working efficiency: 2000m2/h | Number of batteries: 2 |

| Battery voltage: 24V | Battery configuration: 2*67AH |

| Duration: 3 ~ 3.5h | Noise: ≤65dba |

| External size: 1280*900*950mm |

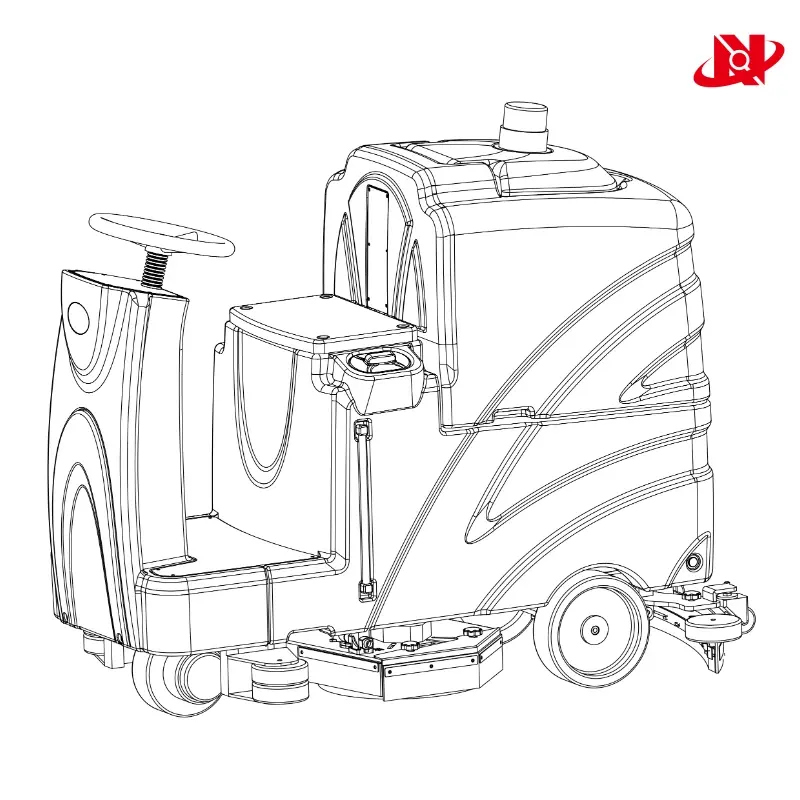

XF-S45 Super suction cleaning machine

- Description

- Download

-

Structure composition:

Disk washing system: Located in front of the bottom of the floor washing machine, the XF-S45 is a single disk washing machine, and the XF-S45B is a double disk washing machine. Brush tray material variety, can be customized nylon brush, wire brush, etc., different ground materials and stain types to choose the appropriate brush tray. We can provide you with a customized service, the brush plate is driven by a motor, can be rotated at high speed, and the floor stains are strongly brushed.

Clean water tank: XF-S45 This clean water tank is 45 liters,

Sewage tank: The sewage tank is 50L. The sewage tank is equipped with a filtration device to prevent impurities in the sewage from blocking the suction system.

Water absorption system: including water absorption scraper and water absorption motor and other components. The absorbent scraper is located behind the bottom of the washing machine, in a long strip shape, and the ground is closely fitted. In the process of pushing the washing machine forward, the water absorption motor drives the water absorption scraper to suck the sewage washed by the brush tray on the ground into the sewage tank, so that the ground is quickly dry.

Power system: The use of electric drive, equipped with high-performance battery for the brush motor, water absorption motor to provide power. Some floor washing machines may also use fuel engines as a power source, but electric floor washing machines are more widely used because of environmental protection and low noise.

Handrail and control parts: ergonomic handrail is provided to facilitate the operator to push the floor washer. The armrest is usually equipped with a variety of control buttons, such as start/stop button, brush disk speed adjustment button, water absorption function switch, etc., to facilitate the operator to flexibly control the running state of the washing machine during the cleaning process.

How it works:

At work, the operator pushes the washing machine forward, first starts the brush motor, makes the brush plate rotate at high speed and contact the ground, and scrubs the ground stains. At the same time, the water in the water tank is evenly sprayed on the ground through the nozzle, which plays the role of softening the stain and assisting cleaning. In the process of brushing, the water absorption system starts, and the water absorption scraper sucks the sewage on the ground into the sewage tank, so as to realize the synchronization of the ground cleaning and drying, and ensure that the ground can be dried quickly after cleaning to achieve a good cleaning effect.

Two, the main characteristics

Efficient cleaning:

The high-speed rotation of the brush plate combined with the washing of clean water and the timely drying of the water absorption system can quickly and thoroughly remove various stains on the ground, such as oil, dust, soil, debris and so on. Compared with the traditional manual cleaning and mopping methods, its cleaning efficiency can be increased several times or even tens of times, greatly shortening the time required for ground cleaning.

According to different ground materials and stain degree, flexible adjustment of brush disk speed, water spraying amount and other parameters, in order to achieve the best cleaning effect.

Environmental protection and energy saving:

Most push-type industrial floor washers are electrically driven, which is more environmentally friendly than fuel-driven cleaning equipment with no exhaust emissions during operation.

It can accurately control the use of clean water and avoid the waste of water resources. At the same time, some advanced floor washing machines are also equipped with an energy-saving mode, which further reduces energy consumption on the premise of ensuring the cleaning effect.

Easy to operate:

After simple training, the operator can easily operate the floor washing machine. The design of its control parts is simple and clear, such as the button on the armrest can easily control the speed of the brush disk, water absorption function.

The ergonomically designed handrail makes the operator more comfortable when pushing the washer, even if it is operated for a long time, it will not feel excessive fatigue.

Easy maintenance:

Wash and replace the brush tray regularly to ensure its cleaning effect. Generally speaking, the replacement operation of the brush disk is relatively simple, just follow the instructions of the manual, loosen the relevant fixed parts, remove the old brush disk, and replace the new brush disk.

Clean the sewage tank regularly, pour out the sewage and clean the inside of the sewage tank to prevent the accumulation of impurities in the sewage from affecting the normal work of the suction system. At the same time, check the wear of the water-absorbing rubber strip. If it is found that the wear is serious, replace the water-absorbing rubber strip in time to ensure the water absorption effect.Applicable scenarios

Factory workshop: The factory floor often has oil, dust, metal debris and other stains, the hand-pushed industrial floor washing machine can efficiently remove these stains, keep the workshop floor clean, and provide a good environment for production activities. For example, automobile manufacturing workshop, machining workshop, electronics factory workshop, etc.

Warehouse: The handling and storage of goods in the warehouse will make the ground produce dust, stains, etc., and regularly use the hand-pushed industrial floor washing machine to clean, which can keep the warehouse floor clean and tidy, and facilitate the storage and management of goods.

Shopping malls and supermarkets: public places such as shopping malls and supermarkets have large area, large flow of people, and the ground is easy to be dirty. The use of hand-pushed industrial floor washing machine for cleaning during non-business hours can quickly restore the cleanliness of the floor and provide customers with a comfortable shopping environment.

Parking lot: There will be dust, dirt, oil and other stains on the ground of the parking lot, and the hand-pushed industrial floor washing machine can effectively remove these stains, keep the parking lot floor clean and beautiful, and facilitate the parking and traffic of vehicles. -